Closed-loop recycled content

Using recycled content needs to be technically possible and environmentally beneficial:

Using recycled content is a complex matter influenced by different variables: the different battery ingredients, availability of recycled content, location of the production plant, impact on production processes, just to mention some. Material resulting from recycled portable batteries is already being used in non-battery related industries precisely because of proximity to the production point.

Virgin materials are essential to produce high performing batteries which last longer and generate less waste. Notwithstanding it is essential to determine which approaches are more environmentally sustainable: closed-loop or open-loop.

For some ingredients this is not possible, for others it’s too complex and it’s uncertain whether it would bring any measurable results: take for instance lead which is used to ppm levels in portable battery manufacturing; or lithium which is simply not available as recycled; or steel where the battery grade is essential in preventing contaminants that cause gassing. It is important to know that in addition to the performance aspect, high purified raw materials are also important for health and safety issues related to batteries (gassing, leaking).

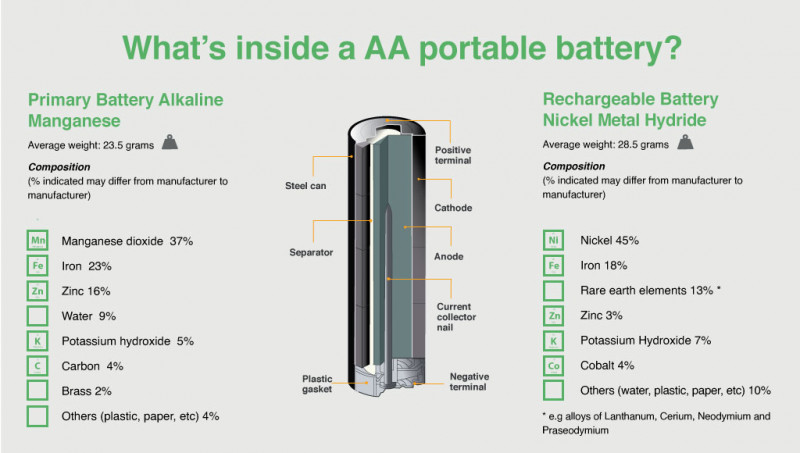

For a better understanding of the substances used for manufacturing both primary and rechargeable portable batteries, have a closer look at this visual. Important to highlight the weight of a AA portable battery: 23,5 grams for primary batteries and 28,5 grams for rechargeable batteries